GAS DETECTION

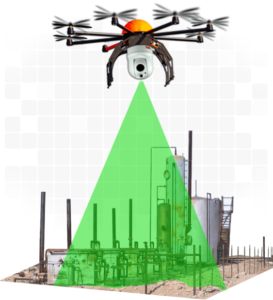

Detecting hydrocarbon gas leaks just became easier with our industry-first miniaturized Optical Gas Imaging camera. Small enough to mount on a UAV, but with more features than other OGI cameras, we can detect gas leaks from the air or the ground.

HYDROCARBON GAS DETECTION

Safety, economics, and regulation all mean that gas detection should be part of your regular inspection routine. Here’s how to do it.

There are many reasons to inspect for gas leaks, safety and economics being the most obvious, but the EPA is now mandating inspections of a vast amount of oil and gas infrastructure under Quad O (OOOO) and Quad Oa (OOOOa) regulations, with severe penalties for non-compliance. MGM’s proprietary “Wide Spectrum Imaging System” can help.

EPA’s New Source Performance Standards & Emission Standards for New, Reconstructed, and Modified Sources

For the first time ever, the EPA is directly regulating methane as a greenhouse gas. The EPA has already established new source performance standards (NSPS) for VOC and SO2 emissions from some operations in the oil and gas sector through regulations codified as “Subpart OOOO.” Because methane comes from many of the same sources as VOCs, the Subpart OOOO regulations already limit methane emissions from the subject sources, even though not regulated as such under that regulation.

On September 18, 2015, the EPA proposed to use methane emissions as a basis to broaden the reach of Subpart OOOO and to change control technology requirements for an extended list of equipment and facilities. This new rule — signed in May by the EPA Administrator — is codified as “Subpart OOOOa” or “Quad Oa.” The new rule has two main parts: (1) mandating that control devices or practices be used to reduce methane and VOC emissions from certain equipment by 95% and (2) fugitive emission leak detection and repair (“LDAR”) requirements that would apply only to well sites and compressor stations.

Quad Oa became law on August 3rd, 2016, and most components were to be inspected by June 3rd, 2017. A recent stay of the compliance deadlines extended the deadline by 90 days to September 3rd, 2017.

To find out if your facilities fall under the Quad Oa regulations, read or download our full Quad Oa Ruling Summary by clicking on this link.

How Do We Find Gas Leaks?

Until now, the primary tool in detecting gas leaks has been a Toxic Vapor Analyzer (TVA), more commonly known as a gas sniffer. This is the device that is used in complying with the Method 21 protocols as set forth in the EPA’s Best Practices Guide for Leak Detection and Repair (LDAR). With the development of infrared cameras that can now detect gas leaks, the EPA has dropped Method 21 as the preferred method of gas detection for Quad Oa compliance in favor of Optical Gas Imaging (OGI).

How Do Optical Gas Imaging Cameras Work?

Everything with a temperature above Absolute Zero emits energy. Infrared cameras work by detecting those energy emissions from only the first 10,000th of an inch of an object’s surface. IR cameras do not see through walls, or through or behind glass, and OGI cameras don’t “see” gas. Anyone that tells you they can do those things with an IR camera does not understand the science behind it and you should think twice about using them. A more in-depth discussion of infrared and IR cameras can be found here, but for now lets focus on gas detection.

How Do I Find Gas Leaks if OGI Cameras Can’t See Gas?

Remember that IR cameras only detect energy emitted from the first 10,000th of an inch of a surface? If that’s the case, then how does an OGI camera “see”, or detect gas? What OGI cameras see is the interruption of radiated or transmitted energy as the gas passes in front of an object and interrupts that wave of energy. To detect that interruption by the gas, an OGI camera operates in a very narrow bandwidth between 3.3 and 3.5 microns. To do that, the sensor in an OGI camera must be cooled to about -200°C.

What are the Benefits of Optical Gas Imaging?

Temperature calculations are non-contact

- Process does not have to be shut down – must be running

- Will not deface or destroy the product

- Transient phenomena or moving objects can be studied

- Fast response, milliseconds

- Temperature calculations of irregular shaped objects

- Pattern observation and evaluation

- Collection of large amounts of thermal data

- Measurement through hazardous atmospheres

- Measurement through special IR windows

- Data easily stored for post analysis and trending

- Safest method of inspection

- Meets criteria for Non-Destructive Testing (NDT)

Why Use Optical Gas Imaging Over Other Methods?

As we noted earlier, the traditional method for finding leaks is by using Toxic Vapor Analysers (TVA) or ‘sniffers’. This method is not without safety implications as it requires the inspector to be close to the source of the emissions and therefore exposed to the hazard. It’s is extremely labor intensive and time consuming as each point or location where a leak might occur has to be inspected individually. In a medium-sized to large plant that has thousands of connections this makes inspection a massive task that can be difficult, dangerous and costly. We have seen numerous figures quoted from different sources but estimates from the US Environmental Agencies indicate that an inspector using the TVA method of inspection can inspect 400-500 connections/points during a full shift. In contrast, the new infrared camera technology is making it possible to inspect upwards of 2000 connections/points per hour. This has allowed for a medium size facility to be inspected in two weeks by a team of two technicians.

Environmental Risk Management

The new camera technology is capable of detecting leaks over considerable distances depending on their size. Using a camera with multiple lenses from the air is an unbeatable way of spotting fugitive gases from barges, storage tanks and gas pipelines. The camera is able to survey several thousand points per hour and can be used to monitor the condition of gasoline refinery installations, natural gas pipelines, transfer stations, supertankers, moving railway tank cars and even landfills emitting methane gas and other chemicals into the environment.

OGI Services from MGM

About our Optical Gas Imaging Services:

- Our OGI inspections are done in strict accordance with all current EPA requirements. Our inspectors are trained and certified thermographers, meaning you get a qualified inspection and report from an industry expert.

- We coordinate our inspections with your legal and HSE departments to ensure your OGI inspection will measure up to industry standards and agency regulations.

- If an aerial inspection is included, flights are conducted by trained and qualified pilots who hold FAA Part 107 Remote Pilot Certificates and meet current ASTM standards.

- Our trained technicians can publish EPA compliant reports and notifications, or help train your personnel to compile reports in-house.

TRUE VISION

Introducing the first OGI camera capable of being mounted on a small UAV platform, while at the same time increasing quality and accuracy.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem sadips ipsums aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem sadips ipsums aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.